News

2026 Best Enameled Aluminum Magnet Wire Options Explained?

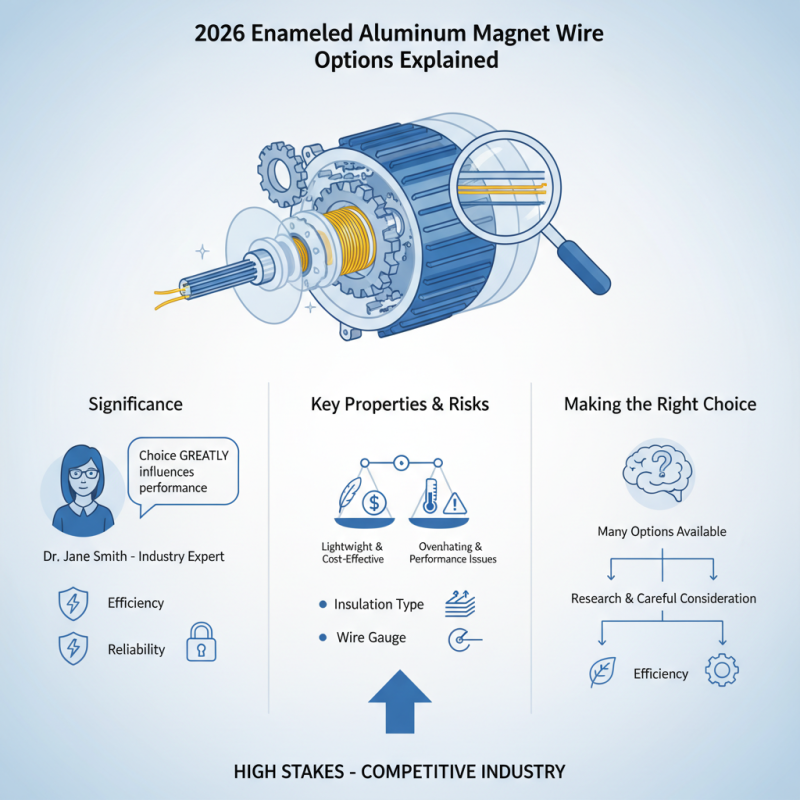

In the realm of electric motors and transformers, the significance of Enameled Aluminum Magnet Wire cannot be overstated. Industry expert Dr. Jane Smith asserts, "The choice of magnet wire can greatly influence performance." This reflects the critical role these wires play in efficiency and reliability.

Enameled Aluminum Magnet Wire stands out for its lightweight and cost-effective properties. However, not all options guarantee the same quality. It is essential to assess various factors such as insulation type and wire gauge. A poor selection might lead to overheating and performance issues, which could undermine project outcomes.

Many professionals face the challenge of choosing the right type. With so many options available, making an informed decision can be daunting. Careful consideration and research are necessary. Each choice carries implications, whether in sustainability or efficiency. The stakes are high in this competitive industry, prompting the need for detailed exploration.

Overview of Enameled Aluminum Magnet Wire

Enameled aluminum magnet wire is essential for many applications. It features a thin layer of insulation that protects the aluminum conductor. This characteristic makes it lightweight and cost-effective compared to copper wire. The aluminum's conductivity is lower than that of copper, but its advantages can be significant in the right environments.

Handling enameled aluminum wire can be tricky. While it’s d durable, the insulation can sometimes be damaged during installation. A nick or scratch can lead to failures. Enameled aluminum wire is often used in motors and transformers. The choice of wire depends on specific needs, such as thermal stability and mechanical strength.

Some users have reported difficulties in soldering aluminum wire. It requires different techniques than copper. Understanding how to effectively work with this material is crucial. There’s a learning curve involved. Recognizing these nuances can enhance performance and reliability in electrical projects.

Key Characteristics of High-Quality Enameled Aluminum Wire

When considering the best enameled aluminum magnet wire, understanding its key characteristics is crucial. High-quality enameled aluminum wire features excellent conductivity. This ensures efficient current flow in various applications. The wire's insulation is another vital aspect. A durable enamel coating prevents short circuits and enhances the wire's lifespan.

Flexibility is an often overlooked factor. High-quality wires can bend without breaking. This makes installation easier in tight spaces. Additionally, corrosion resistance is important. The use of robust materials can keep the wire functional even in challenging environments. However, not all wires perform well under extreme conditions. It's essential to choose wisely and test before use.

Another characteristic is heat resistance. Wires that can withstand high temperatures are more reliable. They can operate under greater loads without damage. But achieving this balance can be tricky. Some wires may overheat if misused or poorly rated. Users must pay attention to specifications to avoid complications.

Comparison of 2026 Enameled Aluminum Magnet Wire Brands

When choosing the best enameled aluminum magnet wire options for 2026, there are several factors to consider. A recent industry report indicates that the demand for aluminum wire is growing steadily. This is due to increasing applications in electric motors, transformers, and other electrical devices. The right choice can enhance performance and durability.

Numerous brands offer a variety of specifications. Some have higher thermal resistance, while others focus on flexibility. Data from industry surveys show that wires with a thicker enamel coating are favored for high-temperature applications. It's crucial to examine insulation type and voltage ratings. These details can significantly impact efficiency and longevity.

**Tips:** Always check the wire's ampacity ratings. This ensures it can handle the required current without overheating. Short-circuited wires can lead to failure. Consider the wire's weight and stiffness, too, as they affect installation.

Another aspect to ponder is the manufacturing process. Some wires may have inconsistencies in enamel thickness. These discrepancies can lead to performance issues over time. Such imperfections warrant careful evaluation before making a purchase. Seek feedback from industry professionals to ensure informed decisions.

2026 Best Enameled Aluminum Magnet Wire Options Explained

| Wire Gauge | Insulation Type | Temperature Rating (°C) | Conductivity (%) | Flexibility Rating | Price per Meter ($) |

|---|---|---|---|---|---|

| 18 AWG | Polyurethane | 180 | 61 | Good | 0.45 |

| 20 AWG | Nylon | 200 | 58 | Excellent | 0.38 |

| 22 AWG | Polyester | 155 | 56 | Good | 0.30 |

| 24 AWG | Epoxy | 130 | 53 | Fair | 0.25 |

| 26 AWG | Polyamide | 180 | 50 | Very Fair | 0.22 |

Applications and Uses of Enameled Aluminum Magnet Wire

Enameled aluminum magnet wire has a range of applications across various industries. It is widely used in electric motors, transformers, and generators because of its excellent conductivity and lightweight nature. According to a recent market analysis, the demand for enameled aluminum wire is projected to grow by 5.4% annually until 2026. This growth is driven by the increasing use of electric vehicles and renewable energy technologies.

Tips: Consider the wire's thickness when selecting enameled aluminum wire. Thicker wire can handle higher currents but may also be less flexible.

Besides traditional applications, enameled aluminum wire is finding its way into more innovative uses. For instance, manufacturers are utilizing this wire in high-frequency transformers. The lightweight quality reduces overall equipment weight, benefiting portable devices. However, some applications may present challenges due to corrosion. Users should be mindful of the environment where the wire is installed.

Tips: Always check the insulation quality. Poor insulation can lead to short circuits and reduced efficiency.

The versatility of enameled aluminum magnet wire makes it appealing. It offers cost advantages over copper, especially in large-scale production. However, users sometimes overlook its heat resistance. Testing this aspect will ensure reliability in demanding applications.

Buying Guide: Selecting the Best Enameled Aluminum Magnet Wire

When selecting the best enameled aluminum magnet wire, understanding its properties is essential. This wire is key in electrical applications. It offers significant advantages over copper wire, such as lower weight and cost. According to industry reports, the global market for enameled aluminum wire is projected to grow by 8% annually through 2026.

Choosing the right wire involves assessing the insulation type and thickness. Different applications may require specific thermal ratings. For example, a wire that withstands high temperatures may be necessary for motors. Data shows that certain insulation materials can enhance wire durability and performance. However, not all choices guarantee quality. It’s crucial to ensure compatibility with your specific application.

Another aspect is the wire gauge. Different gauges affect conductivity and resistance. A thicker wire can conduct better but may be harder to work with. It’s vital to find a balance that fits your needs. Consider the wire’s ease of installation and long-term reliability. Misjudging these factors can lead to inefficiency and higher operational costs later.